Ethanol biofuel is a renewable fuel widely used to reduce dependence on fossil fuels and lower greenhouse gas emissions. Global production now exceeds 110 billion liters annually, making ethanol one of the most commonly used biofuels worldwide.

Understanding what ethanol biofuel is made of is important for comparing efficiency, sustainability, and fuel performance. Different raw materials produce different results in terms of cost, emissions, and availability.

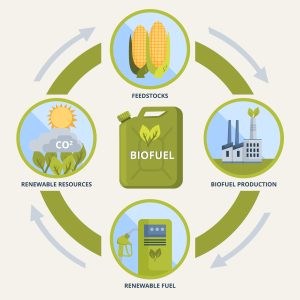

Ethanol is produced from plant-based sugars, starches, and cellulose, allowing it to be replenished year after year. These materials support fuel blending programs that improve octane levels and reduce environmental impact.

In this guide, you will discover the top 10 materials ethanol biofuel is made of, explained in a clear and structured format. Each source is presented to help you understand its role, benefits, and limitations in modern ethanol production.

What Is Ethanol Biofuel Made Of? 10 Best

1. Corn Ethanol – POET Biofuels – Best for Large-Scale Fuel Blending

Corn ethanol produced by POET Biofuels, the world’s largest ethanol producer, dominates global ethanol supply. The United States alone produces over 15 billion gallons annually, accounting for more than 50% of global output. Corn starch is converted into fermentable sugars through enzymatic hydrolysis.

This ethanol type is widely used in E10 and E15 gasoline blends, improving combustion efficiency and reducing tailpipe emissions. Modern corn ethanol facilities also produce distillers dried grains with solubles (DDGS), a valuable livestock feed by-product. This integrated production model enhances overall resource efficiency.

Technological improvements have significantly reduced water use and energy intensity per gallon of corn ethanol. Yield increases now allow more ethanol to be produced on less land than a decade ago. Corn ethanol remains a backbone of renewable fuel standards worldwide.

Pros:

-

High yield

-

Scalable supply

-

Strong infrastructure

-

Fast fermentation

-

Proven technology

-

Job creation

-

Fuel stability

Cons:

-

Food overlap

-

Water demand

-

Fertilizer use

2. Sugarcane Ethanol – Raízen (Shell & Cosan) – Best for Low-Carbon Fuel

Sugarcane ethanol produced by Raízen, a joint venture between Shell and Cosan, is widely regarded as the lowest-carbon commercial ethanol. Brazil produces more than 30 billion liters annually, with sugarcane juice directly fermented into ethanol. This eliminates energy-intensive starch conversion.

Sugarcane ethanol can reduce greenhouse gas emissions by up to 90% compared to gasoline. The fibrous residue, known as bagasse, is burned to generate electricity for ethanol plants. Many facilities export surplus renewable power to national grids.

This ethanol source benefits from extremely high crop yields per hectare. Sugarcane ethanol has become a global benchmark for sustainable biofuel systems. It is widely exported and used in high-ethanol fuel blends.

Pros:

-

Very low carbon

-

High efficiency

-

Energy self-powered

-

Fast fermentation

-

Renewable waste use

-

Export strength

-

Cost effective

Cons:

-

Climate dependent

-

Land intensive

-

Seasonal harvest

3. Wheat Ethanol – Vivergo Fuels – Best for European Markets

Wheat ethanol produced by Vivergo Fuels plays a vital role in Europe’s renewable transport strategy. Wheat starch is enzymatically converted into sugars and fermented into ethanol. This process aligns with strict European fuel quality standards.

Wheat ethanol plants also produce high-protein animal feed, reducing reliance on imported soy. This co-product improves supply-chain efficiency and agricultural profitability. Farmers benefit from stable demand and price support.

Advances in processing technology have improved wheat ethanol’s energy balance. While yields are lower than corn, wheat ethanol remains regionally strategic. It supports emission reduction targets across multiple countries.

Pros:

-

Regional availability

-

Dual outputs

-

Stable supply

-

EU compliant

-

Farmer support

-

Improved efficiency

-

Reduced imports

Cons:

-

Lower yield

-

Food competition

-

Energy input

4. Barley Ethanol – CropEnergies – Best for Cooler Climates

Barley ethanol produced by CropEnergies is well suited for cooler climates where corn productivity is limited. Barley starch converts efficiently into fermentable sugars. This makes it a viable alternative grain feedstock.

Barley fits naturally into crop rotation systems, improving soil structure and reducing pest pressure. Ethanol production provides an additional revenue stream for growers. This diversification enhances farm resilience.

Although barley ethanol yields are lower than corn, process optimization continues to improve output. It remains an important component of regional ethanol portfolios. Sustainability performance continues to improve year over year.

Pros:

-

Climate adaptable

-

Crop rotation

-

Soil benefits

-

Reliable supply

-

Regional security

-

Renewable source

-

Farmer income

Cons:

-

Lower output

-

Processing cost

-

Limited scale

5. Sorghum Ethanol – Green Plains Inc. – Best for Dry Regions

Sorghum ethanol produced by Green Plains Inc. is valued for its drought tolerance and low water requirements. Sorghum requires significantly less irrigation than corn while delivering competitive ethanol yields. This makes it suitable for water-stressed regions.

Both grain sorghum and sweet sorghum varieties can be used for ethanol production. Sweet sorghum provides fermentable juice, while grain sorghum supplies starch. This versatility enhances supply stability.

Sorghum ethanol supports climate-resilient agriculture and long-term sustainability goals. Interest in sorghum-based biofuels continues to grow globally. It is increasingly included in renewable fuel strategies.

Pros:

-

Drought resistant

-

Low water

-

Climate resilient

-

Flexible processing

-

Farmer friendly

-

Sustainable crop

-

Growing demand

Cons:

-

Lower awareness

-

Market access

-

Yield variation

6. Cassava Ethanol – Thai Oil Biofuels – Best for Tropical Production

Cassava ethanol produced by Thai Oil Biofuels is a major biofuel source in tropical regions. Cassava roots contain high starch concentrations ideal for fermentation. The crop thrives in marginal soils.

Cassava ethanol production supports rural economies and industrial energy needs. Processing technologies have improved starch conversion efficiency. This has lowered production costs over time.

When managed responsibly, cassava ethanol balances food and fuel needs. Improved crop varieties have increased yields significantly. It remains a competitive starch-based ethanol source.

Pros:

-

High starch

-

Poor soil growth

-

Affordable feedstock

-

Rural income

-

Tropical adaptability

-

Scalable supply

-

Renewable source

Cons:

-

Storage limits

-

Transport costs

-

Market volatility

7. Sugar Beet Ethanol – Tereos – Best for High-Sugar Efficiency

Sugar beet ethanol produced by Tereos is a key ethanol feedstock in temperate regions. Sugar beets contain 15–18% fermentable sugar, allowing direct fermentation. This reduces processing steps and energy use.

Sugar beet ethanol integrates well with existing sugar industries. By-products are used for livestock feed and soil amendments. This improves resource efficiency.

Seasonal harvesting requires careful logistics planning. Despite this, sugar beet ethanol delivers consistent output. It remains a reliable renewable fuel source.

Pros:

-

High sugar

-

Efficient fermentation

-

Fewer steps

-

Strong yields

-

Dual products

-

Regional fit

-

Low waste

Cons:

-

Seasonal supply

-

Climate limited

-

Storage needs

8. Molasses Ethanol – Wilmar International – Best for Cost Efficiency

Molasses ethanol produced by Wilmar International uses sugar-processing by-products. Molasses contains residual sugars ideal for fermentation. This makes it a cost-effective ethanol feedstock.

Using molasses reduces industrial waste and disposal costs. It supports circular economy principles. Many ethanol plants rely on molasses for supplemental production.

Supply depends on sugar production volumes. Quality can vary by source. Despite this, molasses ethanol remains economically attractive.

Pros:

-

Low cost

-

Waste utilization

-

High sugar

-

Circular economy

-

Easy sourcing

-

Scalable process

-

Eco-friendly

Cons:

-

Limited supply

-

Quality variation

-

Transport issues

9. Cellulosic Residue Ethanol – DuPont Biofuels – Best for Sustainability

Cellulosic ethanol developed by DuPont Biofuels uses agricultural residues like corn stover and wheat straw. These materials do not compete with food crops. Advanced enzymes convert cellulose into fermentable sugars.

Cellulosic ethanol can reduce greenhouse gas emissions by up to 85%. It represents the next generation of biofuel technology. Research investment continues to drive innovation.

Production costs remain higher than conventional ethanol. However, efficiency improvements are closing the gap. Cellulosic ethanol is critical for long-term decarbonization.

Pros:

-

Non-food source

-

High emission cuts

-

Waste utilization

-

Future-ready

-

Advanced technology

-

Incentive supported

-

Sustainable fuel

Cons:

-

High cost

-

Complex processing

-

Limited plants

10. Grass & Wood Ethanol – Abengoa Bioenergy – Best for Advanced Biofuels

Grass and wood ethanol produced by Abengoa Bioenergy uses switchgrass and forestry residues. These feedstocks grow on marginal land and require minimal inputs. They do not interfere with food production.

This ethanol pathway supports long-term energy independence. Forestry waste utilization also reduces wildfire risk. Environmental benefits extend beyond fuel use.

Commercial-scale deployment continues to expand. Conversion efficiency improves with ongoing research. Grass-based ethanol represents future-focused bioenergy.

Pros:

-

Non-food biomass

-

Marginal land

-

Carbon reduction

-

Renewable growth

-

Forestry benefits

-

Long-term supply

-

Innovation driven

Cons:

-

Capital intensive

-

Slow scaling

-

Technical complexity

What Is Ethanol Biofuel Made Of (FAQs)

1. What is ethanol biofuel made of?

Ethanol biofuel is made from sugars, starches, and cellulose derived from crops and plant-based biomass.

2. Which ethanol source is most sustainable?

Sugarcane and cellulosic ethanol offer the lowest lifecycle emissions.

3. Is ethanol biofuel renewable?

Yes, ethanol is renewable because it comes from regrowable plant materials.

4. Does ethanol reduce carbon emissions?

Ethanol reduces emissions by 20–90%, depending on feedstock and process.

5. Can ethanol replace gasoline?

Ethanol blends significantly reduce gasoline use but require compatible engines.

6. Is ethanol safe for engines?

Ethanol improves octane and burns cleaner in approved fuel systems.

7. Which countries lead ethanol production?

The United States and Brazil are the largest global producers.

Conclusion

Ethanol biofuel is a versatile and renewable fuel that reduces reliance on fossil fuels and lowers emissions. Corn ethanol remains the best overall option due to its high yield and established infrastructure.

Sugarcane ethanol is the runner-up, offering very low carbon emissions and efficient energy production. Both feedstocks demonstrate how different materials can support sustainable fuel production at scale.

Advanced sources like cellulosic residues and grass-based ethanol show promise for long-term sustainability. They provide non-food alternatives and reduce greenhouse gas emissions significantly.

In summary, understanding the top 10 ethanol feedstocks helps identify the most efficient and eco-friendly options. Choosing the best or runner-up source depends on local conditions, availability, and production goals.

Recent Posts

When To Apply Liquid Copper Fungicide?– Expert Recommendations

Applying liquid copper fungicide at the correct time is essential for maximum disease control and plant safety. Because copper functions as a protectant fungicide, it must be applied before infection...

Do I Need To Wear A Mask When Spraying Copper Fungicide? 10 Best Reasons Why

Spraying copper fungicide is a common practice in gardening and agriculture, but many people underestimate the health risks associated with inhalation exposure. Fine copper particles and aerosolized...